We’re a small team of pragmatic builders who start with constraints (cost, labor, logistics) and design systems that turn them into leverage. Every decision is grounded in what scales, what lasts, and what works in the market.

Our Team

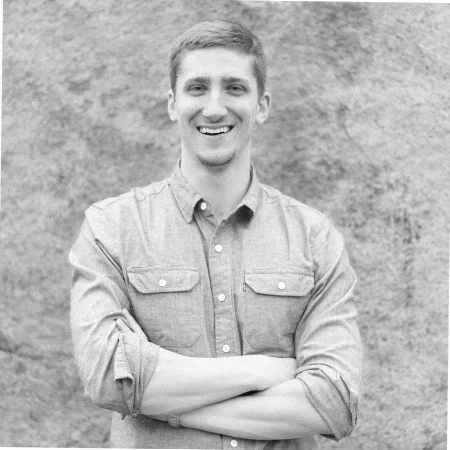

David Ashton

David is the founder and CEO of Canopii. He leads engineering project management, grant writing and fundraising, and business development. Before Canopii, he worked as a contract engineer at Sherpa Design on research projects spanning AR and VR systems and military optics. Earlier in his career, he led a five person team to develop a robotic system that automated trellis wire twining for the hops industry.

Outside work, David enjoys spending time with his daughter, exploring the world with his wife, and experimenting in the kitchen. He has logged an embarrassing number of hours playing Civilization V and The Elder Scrolls, is always hunting for new songs, and learning about history. He has given up on watching the Sacramento Kings lose but still enjoys watching the 9ers almost win.

Founder & CEOSam Pepperwood

Sam Pepperwood is a Senior Mechanical Engineer at Canopii, where he leads the mechanical design of Canopii’s system, with a clear focus on reliability and cost. Before Canopii, he spent 14 years as a contract engineer at Sherpa Design, working across RV chassis, military electronics, and precision infrared optics.

Outside of work, Sam is a fair-weather bike and motorbike enthusiast with a packed garage of rides that always need wrenching and oil puddles that always need cleaning. When the seasons are cold, he’s tinkering with retro videogames and marathoning horror movies. He’d love to discuss metal forming, carb tuning, or the finer points of the Child’s Play movies with you, whichever you prefer.

Senior Mechanical EngineerOperations & Revenue ManagerRyan Tovey

Ryan Tovey leads Operations and Business Dev at Canopii, overseeing HR, finance, sales and marketing, and outreach to drive the company’s growth. Before Canopii, he was Director of Retail & Hospitality at Bell’s Brewery, where he developed talent across teams, strengthened brand relevance, and helped deliver consistent, high-quality customer experiences. He also held sales and marketing roles at Sierra Nevada Brewing Co., building deep experience in brand ambassadorship, sales training, and market expansion.

At Canopii, Ryan is focused on sharpening our go-to-market strategy so dependable, pristine product shows up where it’s needed. Off the clock, he’s hiking, reading, or clearing a podcast queue - always up for talking sports, fantasy/sci-fi, produce supply chains, or craft beer.

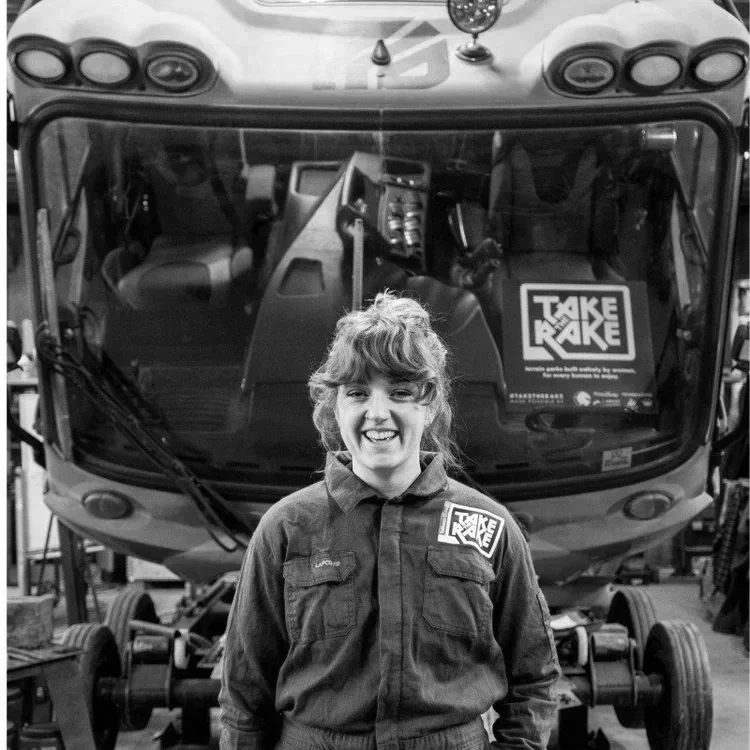

Electromechanical TechnicianChloe Butel

Chloe Butel is Canopii’s Electromechanical Technician, building and troubleshooting our mechanical and electrical systems, sourcing parts, and mechanical engineering design. With a Plant Science degree and a deep background in organic farming and greenhouse operations, she helps us push for real efficiency—both biological and mechanical.

Before Canopii, Chloe spent years running heavy machinery in the snow sports world, traveling nationwide to build freestyle terrain for events like X-Games and Take the Rake. She also worked at Twist Bioscience, where she picked up the magic of lab automation and high-throughput DNA synthesis. Outside of work, she keeps her 1988 Toyota pickup running, chases live music around Portland, snowboards in winter, and surfs in summer.

Senior Software EngineerRyan Jones

Ryan Jones is a Senior Software Engineer at Canopii. He writes production code, reviews automation designs, and improves the performance of our greenhouse robots. Before Canopii, he worked as an Automation Engineer at Loupe, Olympus Controls, and Oregon Tool, where he designed, built, and programmed robotics and automation systems.

Ryan is excited about bringing computer vision and machine learning into the greenhouse to take Canopii’s produce to the next level. He loves collaborating across disciplines and is eager to help grow Canopii’s local partnerships. Outside of work, Ryan’s into sports, country dancing, and craft beer. Ask about the Denver Broncos or Portland Trail Blazers and you’ll get a earful.

Junior GrowerGriffin Crabtree

Griffin Crabtree is a Grower at Canopii, where he focuses on yield and operational analysis, fertigation management, and pest control. Before Canopii, he worked at Chemeketa Community College as a Dry Farmer. Earlier in his career, he held a variety of roles such as a farmhand at Santos Family Farms and as a cook.

Griffin is passionate about improving yield data and deepening his horticultural knowledge. Outside of work, Griffin can be found playing guitar, rock climbing & backpacking/hiking. Based in Beaverton, he always welcomes a good conversation about plants and music.

We envision a world where the food supply chain is driven by many, not just a few. We are here to empower small and mid-sized food producers and suppliers to compete effectively, fostering a sustainable and varied agricultural ecosystem.

Our Pillars

-

Sustainable Innovation

We've reimagined every step of the growing process to prioritize sustainability—obtaining organic certification, dramatically reducing chemical use, minimizing single-use plastics, maximizing energy efficiency, and optimizing water usage. By enabling year-round local production and continuous harvests, we reduce food miles and spoilage. Our technology sets a new standard for ultra-fresh, untouched local produce.

-

Local Food Security

Our solution significantly reduces dependence on centralized production, stabilizing local food prices by minimizing cold supply chain costs and retaining economic benefits within the community. By making fresh produce accessible even in food deserts, we’re promoting healthier communities and creating opportunities for high-tech agricultural jobs. This hyper-local approach strengthens both food security and local economic resilience in the face of global challenges.

-

Year-Round Crop Customization

Unlock year-round production of high-quality crops with our farm's controlled environment technology. Seamlessly adjust your growing strategy to meet niche market demands for specialized leafy greens and herbs. Our system not only optimizes cultivation, but also simplifies day to day operations, allowing you to diversify your business or take time off with confidence in your crop's success. Canopii’s technology ensures that high-demand, local produce is always in season.

-

Scalable Growth

Our system enables flexible, incremental growth for anyone producing fresh food—retailers, foodservice operators, institutions, and growers alike. Customers can start with a single on-site farm and expand unit by unit as demand grows. Automated greenhouse operations reduce labor dependence, allowing production to scale without increasing headcount. The result is consistent, year-round output, new revenue opportunities, and the ability to add new crops over time—making local food production economically viable at scale.

-

Vertical Integration

Our end-to-end solution makes advanced agricultural technology attainable for fresh food producers of all sizes. By streamlining operations from farm to retail, we significantly reduce overall costs and enhance affordability through vertical integration. Our farms competitive pricing ensures a rapid return on investment, improving our customers' margins while offering consumers better prices. This efficiency transforms the economics of modern farming, with year-round production of fresh, local, and affordable produce.

David Ashton didn’t set out to disrupt agriculture. He saw a problem and kept coming back to it.

Growing up in Sacramento and later studying Agricultural Engineering at Cal Poly San Luis Obispo, Ashton spent years surrounded by acres of leafy greens grown in regions with little water. During California’s historic drought, he watched those crops produced at enormous scale, only to be packed up and shipped across the country. The system was efficient at volume, but designed without regard for distance, resource use, or waste — and its inefficiencies were treated as normal.

After college, Ashton worked in defense and consumer technology. The teams were well funded. The hardware programs were ambitious. The work was challenging. Over time, it felt far from the problems he wanted to solve.

At night, while his wife was in medical residency, he worked on a different idea. He began sketching a food production system from the ground up. He focused on margins, labor, operating costs, and durability. He approached it like a farmer.

That work became Canopii.